Contact Us

Company address: Floor 1, Building 6, Zhongguancun Digital Economy Industrial Park, Baoding, 777 Lixing Street, Baoding City

Office telephone:

Technical Department:

Sales Department:

Website:http://www.hbswdq.com

E-mail:swsc@hbswdq.com

On-line Monitoring System for Gas in Transformer Oil by MSDGA Laser Photoacoustic Spectroscopy

Key words:

Classification:

- Product Description

-

1. Status of gas monitoring in oil

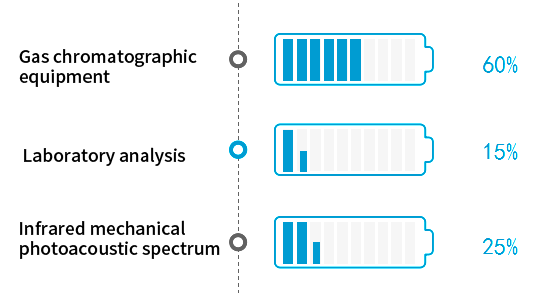

Gas chromatography equipment needs to be in a good environment laboratory and after strict calibration to obtain accurate data. After the laboratory equipment is simplified and transplanted to the online equipment in the outdoor harsh environment, the accuracy of the online data is too poor and only repeatability is available for reference. Therefore, it can only provide reference for the change trend of the transformer that has failed, and it cannot achieve early warning, and it is impossible to analyze the operating state of the transformer that works normally.

On-line gas chromatography equipment, like laboratory equipment, still requires regular calibration and frequent replacement of consumables such as carrier gas chromatography columns, which consumes a lot of labor costs.

For decades, global high-voltage power-related companies have been committed to how to achieve effective and low-cost real-time online monitoring of the operating status of large oil-immersed power equipment (including transformers), and improve the safe and reliable performance of power grid operation and operating efficiency.

At present, there are several traditional solutions:

(1) The laboratory uses a gas chromatograph for analysis

(2) On-line gas chromatography equipment

(3) Infrared mechanical photoacoustic spectroscopy equipment

(4) Optical fiber photoacoustic spectroscopy equipment

2. Product Overview

This product is the application of advanced sensing technology in the basic core technology research project of the Internet of Things of the State Grid. It analyzes the gas in oil of oil-immersed power equipment, especially for real-time online monitoring and fault warning of large-scale high-voltage, ultra-high voltage and ultra-high voltage power transformers.

The key components of the system are designed independently: narrow linewidth semiconductor laser, specially modulated laser wavelength, which avoids the cross interference of various gases and improves the detection accuracy of trace gases; the sub-ultrasonic resonant frequency photoacoustic cell of independent patented technology has small size and high response efficiency, which reduces the influence of external noise on the system, so that the system has good stability and accuracy.

The device through the multi-network inspection, running well, data stability, repeatability have reached a good expected index, its reliable monitoring and analysis and subsequent maintenance-free performance, has the ability to serve the safe operation of the transformer, while saving considerable operation and maintenance costs for users.

3. Analysis of the current situation of gas monitoring in oil

3.1 laboratory gas chromatography detection

Poor timeliness, only repetitive data available for reference

3.2 on-line gas chromatography

On-line gas chromatography analysis equipment, like laboratory equipment, requires regular calibration and frequent replacement of consumables such as carrier gas chromatography columns, which consumes a lot of labor costs.

3.3 infrared mechanical photoacoustic spectroscopy

It can only provide reference for the change trend of transformer fault, and can not meet the requirements of early warning and operation state analysis. Because it is a joint venture, it is expensive and the core technology is in the hands of foreign companies.

4. Current Issues

4.1 standard defect: The testing standard failed to keep pace with the times, and even required the indexes and methods of scientific research in the laboratory to the working condition site, which made the equipment difficult to realize or expensive to popularize!

4.2 over-monitoring: All relevant equipment will be on! As the monitoring means of different manufacturers are systematic and the coordination construction is complicated, only the model station project can be implemented, which cannot be widely promoted and resources cannot be reasonably used!

Inadequate 4.3 monitoring: The expensive equipment leads to difficulties in funding arrangements or the lack of functions of the equipment itself, and the failure to widely install effective monitoring equipment and access to the power Internet of Things!

4.4 device problems: The equipment itself is affected by factors such as field temperature, humidity and vibration, and has insufficient anti-interference ability, or complex maintenance, does not have self-inspection and self-diagnosis function, and cannot be reported after a failure occurs!

4.5 business issues:After the equipment is installed, it fails to operate in time for a long time!

5. Technical route

In response to the urgent needs of the market, our company developed an on-line monitoring and early warning equipment for dissolved gases in oil suitable for outdoor use. The core technology is dynamic headspace negative pressure oil and gas separation and laser photoacoustic spectroscopy gas detection.

5.1 oil and gas separation: This unit is the first process of equipment operation. The trace gases in the transformer oil are safely and stably separated and transferred to the detection unit. At the same time, the cleaner oil sample after degassing is returned to the transformer. We have summarized the advantages and disadvantages of blowing bubble degassing and vacuum degassing applied in the field for many years, and developed a more efficient new dynamic headspace negative pressure oil and gas separation device, which greatly shortens the detection time and improves the working efficiency of the equipment.

5.2 gas detection: This unit is the key process of equipment operation. The separated mixed gas is directly measured accurately without processing, and then the gas is discharged into the air. The advanced laser sensing technology is adopted to solve the influence of environmental temperature, vibration, noise, cross interference and other factors in the traditional scheme. The developed gas detection unit improves the detection accuracy, has no mechanical motion structure, and greatly extends the working life of the equipment.

6. How to choose

6.1 Series Products

Various monitoring devices will have a series of products corresponding to different application scenarios. Taking the on-line monitoring and early warning device for gas in laser photoacoustic spectroscopy oil as an example, there are series of products such as single-component, small-component and multi-component corresponding to different grades of transformers to avoid excessive monitoring or insufficient monitoring.

6.2 Product Features

It is suggested that the on-line monitoring and early warning device of gas in oil by laser photoacoustic spectroscopy should be taken as the basic function, the oil quality analysis (oil water content, dielectric constant, etc.) as the auxiliary function, and the iron core grounding current as the supplementary function. In the budget to allow the optional gas and local release positioning function. Maintenance-free respirators are particularly important for transformers without diaphragm capsules, and those with diaphragm airbags also have a certain protective effect.

6.3 fault judgment

Different failures will produce different gases, and the gas content varies with the degree of failure. We can analyze what kind of failure and the degree of failure according to different gas concentrations.

(1) Acetylene is recognized as the key fault gas related to discharge, but the gas concentration is very low, so the global manufacturers are currently trying to tackle how to accurately measure acetylene with higher cost performance;

(2) Ethylene, methane, and acetylene are analyzed by David's triangle method to make reasonable judgments on the transformer's partial discharge, arc, overheating and other important gases. The outstanding advantage of David's triangle method is that it retains some data that are missed by the three-ratio method because they fall outside the provided ratio limit. If the ratio point falls in which area, the fault type corresponding to the area is the fault type corresponding to the ratio, and visualizing the location of the gas can always provide a diagnostic result with a low error rate. Although the three-ratio method is compared with ethane, it only serves as a reference for temperature analysis and can only be applied to serious faults, whether mineral oil or vegetable oil, and its ratio is meaningless in normal or mild faults. So the early warning system can not use the three ratio method, no need to monitor ethane!

(3) Hydrogen will be generated in all faults, but the specific fault cannot be confirmed. It is suitable for low-pressure oil-immersed equipment to simply judge whether there is a fault.

(4) Carbon monoxide and carbon dioxide can also be used to reflect the failure of oil-paper solid insulation, but there is no strict boundary and the law is not obvious. It should be comprehensively analyzed with the change of methane and acetylene through David's triangle method, so these two gases can be used as reference.

(5) Oil quality analysis and micro-water content can further diagnose what causes the transformer to fail.

Comparison of 6.4 monitoring principles

Comparison Items laser photoacoustic spectroscopy optical fiber photoacoustic spectroscopy infrared mechanical photoacoustic spectroscopy On-line gas chromatography Routine maintenance No consumables, no maintenance No consumables, no maintenance No consumables, no maintenance Consumable, frequent maintenance Reliability High Low Medium Low Accuracy High Low Medium Low Repeatability High Medium High Medium Anti-vibration High Low Low Medium comprehensive cost Medium Medium High Medium Core device Tunable single-wavelength narrow linewidth

semiconductor laser

Precise pointing measurement

Life span of up to 10 years

Tunable single-wavelength narrow linewidth

semiconductor laser

Precise pointing measurement

Life span of up to 10 years

Non-Modulated Wide Spectrum Infrared Light Source

A variety of glass filters caused

cross interference problem

Short light source life

Chemical Chromatography Module

Online runtime only

Repeatability data can refer

Other basic substandard

Core Module Photoacoustic cell light and high response

5cm long weight 20 grams

Modulation Frequency of Ultrasonic Segment

The photoacoustic cell weighs about 1000 grams

Modulation frequency 1-2KHz

In the range of ambient noise

Opto-acoustic module weighs 5000 grams

Modulation frequency 1-2KHz

In the range of ambient noise

chromatographic unit Operation mode Electric modulation, long life

No mechanical moving parts, not affected by the outside world

Electric modulation, long life

However, the optical fiber part is easily affected by external vibration and noise.

Mechanical turntable modulation

Life is not long

Interference by environmental noise vibration

Affected by environment

Short life

Poor stability reliability

7. Product advantages

• Narrow linewidth semiconductor lasers

The specially modulated laser wavelength avoids the cross interference of various gases and improves the accuracy of trace gas detection;

• Independent patent technology photoacoustic conversion pool

The self-patented ultrasonic resonant band photoacoustic conversion pool has small size, high response efficiency, reduces the influence of external noise on the system, and makes the system have good stability and accuracy.

• Good anti-interference and accuracy

The specially designed high sensitivity sub-ultrasonic microphone reduces the influence of the external environment and noise on the system, so that the system has good anti-interference and accuracy.

• Good operational stability

Good operation, data stability, repeatability have reached a very good expected indicators, its reliable monitoring and analysis and subsequent maintenance-free performance, to ensure the safe operation of the transformer, while saving users considerable operation and maintenance costs.

8. Functions and indicators

Product Model Product Introduction Application Scenarios Installation method two components

MSDGA-2

Measurement of C2H2, H2(H2O, oil quality analysis) Fault early warning monitoring is carried out for distribution network transformers, self-contained power plant transformers and other oil-immersed power equipment. Wall-mounted five components

MSDGA-5

Measurement of C2H2, CH4, C2H4, H2, CO(H2O, oil analysis) For 110kV transformer, through the David triangle diagram method, three ratio method and other methods to do fault analysis and diagnosis, can be installed on the transformer bracket, does not occupy the ground space. Cabinet type Eight components

MSDGA-8

C2H2, CH4, C2H4, H2, CO, CO2, C2H6, H2O (oil quality analysis) For 220kV and above voltage level transformer fault early warning monitoring, and through the David triangle diagram method, three ratio method and other methods to do fault analysis and diagnosis, optional oil quality analysis module and partial discharge monitoring module. Cabinet type Operation index Power AC220V <1KW Weight <100KG Overall dimension Standard 19 'cabinet or wall mount enclosure Ambient temperature -40 ℃ ~ 55 ℃ Ambient humidity 10~95% Control mode Automatic, menu, manual control optional Communication mode RS485/RJ45/fiber/4G wireless Technical index ppm(μL/L) detection parameter Minimum detectable quantity Detection range Measurement error limit (Class A) Acetylene C2H2 0.2 0.2~1000 ± 0.2 or ± 20% Ethylene C2H4 0.5 0.5~1000 ± 0.5 or ± 30% Methane CH4 0.5 0.5~1000 ± 0.5 or ± 30% Hydrogen H2 2 2~2000 ± 2 or ± 30% Carbon monoxide CO 25 25~5000 ± 25 or ± 30% Carbon Dioxide CO2 25 25~15000 ± 25 or ± 30% Ethane C2H6 0.5 0.5~1000 ± 0.5 or ± 30% Slight water H2O 0 0-100% ±5%

Product inquiry

Related Products